ABOUT US

At Alien’s 3D Infotech, we fuse advanced 3D Printing technologies with real-world precision to create functional prototypes, custom parts and design models across industries.

We specialise in SLA (Stereolithography) 3D Printing, as well as FDM, SLS, DMLS, vacuum and cutting technologies — enabling exceptional accuracy and detail in everything from jewellery and architecture to engineering and media.

From digital concept to physical model — we bring your ideas to life layer by layer.

Industries We Serve

Tailored prototyping for every imaginable sector.

From industrial product developers to medical innovators — our 3D Printing and prototyping services are trusted across sectors where detail, durability and development speed are non-negotiable.

How 3D Printing Helps:

• Prototype parts before investing in injection moulds

• Validate fit, tolerance and design complexity

• Cut down mould correction cycles with quick iterationsUseful for:

• Plastic component prototyping

• 3D Printing for mould designers

• Injection mould trial components

• Low-volume tooling validationHow 3D Printing Helps:

• Craft custom ornamental shapes with ultra-fine details

• Small-batch production or sample runs for clients

• Perfect surface finish for painting, coating or displayUseful for:

• Toy 3D prototyping

• Resin trophy model printing

• Gift item 3D Printing

• Custom artifact 3D PrintingHow 3D Printing Helps:

• Print cases, enclosures, brackets or connector housings

• Validate ergonomics and part interlocks

• Rapidly test form, fit and finishUseful for:

• Electronics enclosure 3D Printing

• Casings for wearables

• Mobile accessory prototyping

• Component fitting modelsHow 3D Printing Helps:

• Translate early ideas into testable 3D forms

• Explore design feasibility without tooling cost

• Iterate and pivot quickly before investing in scaleUseful for:

• Startup 3D printing services

• Rapid idea prototyping

• Concept model 3D Printing

• R&D PrototypingHow 3D Printing Helps:

• Create experimental fixtures and low-run prototypes

• Validate industrial designs with high-resolution test models

• Develop proof-of-concept parts for labs and field testsUseful for:

• Automotive R&D model 3D Printing

• 3D Printing in industrial research

• Prototype testing for engineers

• Experimental assembly partsHow 3D Printing Helps:

• 3D Print anatomical models, crowns, bridges and aligners

• Design biocompatible resin models for surgeries and trials

• Customize surgical planning tools like guides and patternsUseful for:

• Dental crown 3D Printing

• Resin aligner 3D model Printing

• Surgical guide 3D Printing

• Ortho jaw model prototypingHow 3D Printing Helps:

• Patient-specific bone and implant models

• Design functional jigs, fixtures and drill guides for surgeons

• Enable better surgical outcomes through visualizationUseful for:

• Orthopedic surgical planning 3D Print

• SLA anatomical model Printing

• Joint replacement guides

• Resin jigs for operation preparationHow 3D Printing Helps:

• High-detail wax/resin models for lost casting

• Rapid design iteration for custom orders

• Small batch production for boutique brandsUseful for:

• 3D Print for Jewellery wax model

• Gold casting prototypes

• Fine detail ornament 3D Printing

• Custom jewellery 3D PrintingHow 3D Printing Helps:

• Scale models of buildings, interiors and landscapes

• Detailing for façade design and material textures

• Ideal for client demonstration and project approvalsUseful for:

• Architectural model 3D Print

• Interior prototype 3D Printing

• Real estate pitch models

• 3D Printing for architectsHow 3D Printing Helps:

• Character models, props and costume prototypes

• Stop-motion miniatures or cinematic test pieces

• Print-ready assets for VFX pipelinesUseful for:

• Animation character 3D Printing

• Film prop 3D Printed model

• VFX prop prototyping

• Gaming miniature 3D Print

GALLERY / OUR WORK

Real Projects. Real Results.

Our Capabilities

Whether you're looking to develop a proof of concept, functional part or architectural model, we offer agile, end-to-end solutions tailored to your industry, timeline and vision. Every project is handled with attention to detail, technical accuracy and future-focused thinking.

OUR 3D PRINTING SERVICES INCLUDE -

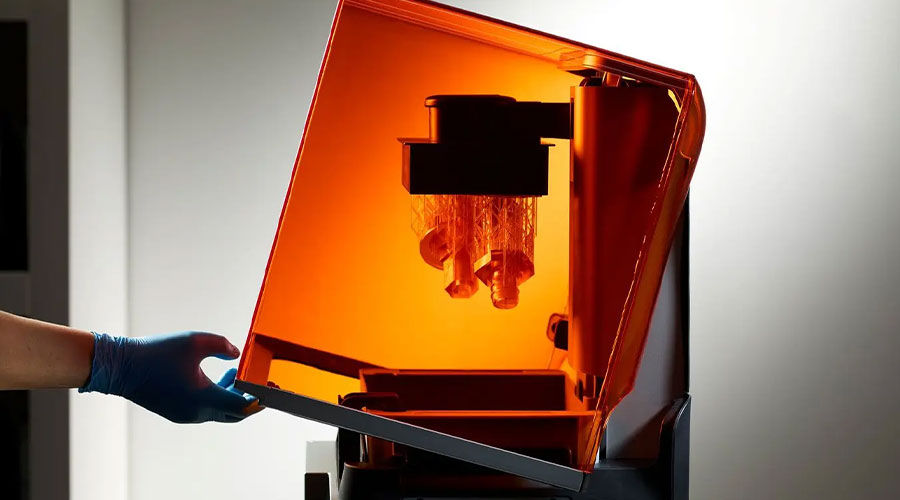

SLA (Stereolithography)

UV Laser + Resin = Ultra-Fine Detail

How It Works:

-

Photopolymer resin is cured layer by layer with a UV laser

-

Build platform lowers as new layers form

-

Post-processing involves washing, UV curing, support removal and sanding

Key Features:

-

Ultra-high resolution for intricate detail

-

Materials: rigid, flexible and transparent resins

-

Smooth surface finish (almost injection mould quality)

-

Moderate speed, ideal for visual and design-grade models

-

Supports required and manually removed

Best For:

Jewellery, dental, fashion and product design prototypes

FDM (Fused Deposition Modelling)

Melted Filament. Strong, Functional Parts.

How It Works:

-

Thermoplastic filament is heated and extruded through a nozzle

-

Layers are deposited sequentially and solidified as they cool

-

Basic post-processing may include trimming or smoothing

Key Features:

-

Moderate resolution, ideal for durable models

-

Materials: PLA, ABS, PETG and TPU

-

Visible layer lines (can be finished as needed)

-

Cost-effective and quick turnaround

-

Minimal support structures required

Best For:

Functional prototypes, mechanical parts, jigs and fixtures

SLS (Selective Laser Sintering)

Powder-Fused Precision. No Supports Needed.

How It Works:

-

Laser sinters nylon powder layer by layer

-

Unfused powder supports the part during the build

-

No support structures required

Key Features:

-

High strength with functional accuracy

-

Materials: Nylon 12, PA11 and glass-filled nylon

-

Matte, grainy finish with good durability

-

Supports complex internal geometries

-

Excellent wear and impact resistance

Best For:

End-use parts, enclosures, functional prototypes and low-volume production

DMLS (Direct Metal Laser Sintering)

From Metal Powder to Precision Component.

How It Works:

-

High-powered laser fuses layers of metal powder

-

Parts are built on a metal base plate

-

Post-processing includes heat treatment, support removal and finishing

Key Features:

-

High-resolution, fully functional metal parts

-

Materials: Stainless steel, titanium, aluminium and cobalt chrome

-

Exceptional strength and repeatability

-

Ideal for fine internal channels and detailed geometries

-

Requires advanced post-processing

Best For:

Aerospace, automotive, surgical implants and tooling applications-

Reverse Engineering: Bridging the Physical and Digital Worlds

We digitally reconstruct real-world objects by studying their shape, function and structure — ideal for replication, redesign or enhancement.

How It Works:

-

Physical object is 3D scanned using high-accuracy tools

-

Scan generates a point cloud or mesh

-

Data is cleaned and converted into usable CAD models

-

Files are ready for modification, analysis or re-manufacturing

Key Features:

-

Captures accurate geometry of any component

-

Enables legacy part recreation

-

Compatible with all major CAD/CAM/CAE workflows

-

Supports design analysis, modification and improvement

Advantages:

-

Ideal for R&D, tool development, product upgradations

-

Helps preserve discontinued parts or replicate competitor components

-

Essential for industries with aging infrastructure or manual designs

-

3D Modelling: Turning Imagination into Digital Form

We convert ideas into precise digital 3D models for printing, simulation or digital visualization — from concept sketches to CAD-perfect files.

How It Works:

-

Concepts are digitally sculpted using CAD tools or scanned data

-

Designs can be created from scratch or references

-

Models support real-world scale, proportions and mechanics

-

Output files prepared for SLA printing, rendering or simulation

Key Features:

-

Supports all 3D design styles: polygonal, parametric, NURBS

-

Compatible with engineering, product and animation workflows

-

High-precision models for visual, functional or testing purposes

-

File formats include STL, OBJ, STEP, IGES and more

Advantages:

-

Ideal for industrial designers, startups and creators

-

Supports product development, animation, VR/AR and more

-

Saves cost and time in prototyping & production

-

Industrial Design: Where Innovation Meets Functionality

From idea sketches to full-scale working models, we help shape concepts into market-ready prototypes that balance function, usability and style.

How It Works:

-

Start with conceptual sketches or references

-

Move to CAD modelling and structural visualization

-

Build functional or visual prototypes for testing and feedback

-

Refine designs for manufacturing, scale-up or investor demonstration

Key Features:

-

Services include:

-

Idea Sketches – Quick design exploration

-

Technical Drawings – Dimensions, mechanisms, materials

-

Functional Prototypes – Test-fit, mechanical behavior

-

Pre-Production Units – Ready-for-market prototypes

-

-

Enables usability testing, ergonomic validation and iterative design

Advantages:

-

Ideal for startups, OEMs, consumer products and design firms

-

Speeds up go-to-market with tangible, testable units

-

Supports design validation before tooling

-

Why Partner with Alien’s 3D Infotech?

Precision Engineered. Innovation Delivered.

-

3D Printing Experts: Dedicated to high-details, smooth-finish and accurate printing

-

Fast Turnaround: Quick delivery without sacrificing quality

-

End-to-End Workflow: Design to prototyping, all under one roof

-

Flexible Manufacturing: From one-off to small batch production

-

Industry-Grade Equipment: Only the best, calibrated tech

-

Cross-Industry Solutions: Jewellery, fashion, automotive, education and more

-

Rigorous Quality Checks: Every part tested, every layer precise

Innovation Across Sectors

We’ve supported creators, designers and engineers across diverse industries.

Automotive

Robotics & Engineering

R&D & Academia

Jewelry & Fashion

Healthcare Devices

Consumer Electronics

Architecture & Urban Planning

Product Design

CONTACT US

Let’s Build What’s Next!

Have a product idea or a design file ready? We’ll help you bring it to life with precision and speed.